Customize the most personalized gloves and mittens.

Custom gloves, Ski gloves mittens, Best ski mittens

Manufacturing and customizing the warmest ski gloves, snow gloves, and other winter accessories.

Custom gloves, Ski gloves mittens, Best ski mittens

We offer personalized and customized services to our clients worldwide. In addition to our retail customer base, which includes wholesalers, distribution companies, supermarkets, and others, we also produce custom gloves for the military, police, fire departments, and all levels of government.

Glove List

We customized gloves and mittens for everyone

A pair of gloves is very important when playing outdoor sports in winter. It protects your hands effectively. Choosing the right gloves depends on how you will use them and what your activity or industry needs. We are a leading manufacturer and supplier of gloves. We manufacture and wholesale the best mittens, custom gloves, ski gloves mittens, and winter gloves. We know the needs of different groups. So, we provide top solutions for designing and making gloves. We can create gloves in different colors, patterns, and styles. They’re stylish and useful. We customize the best ski mittens for you. Whether you ski, run, or work from home, our gloves will match your style.

History and function of ski gloves and mittens

Labor protection tools evolved into professional equipment.

Ski gloves emerged in the early 20th century. They were first used for Nordic winter activities to keep hands warm. As skiing has developed, its role has changed. Now, it’s more than just a warm layer; it offers combined protection. The rise of China’s ski gloves began in the 1980s in Jiaxiang County, Shandong Province. After over 40 years, the county is now the world’s biggest ski glove production base. The growth of the glove industry shows how popular skiing has become. It also highlights advances in materials science and manufacturing.

Ski gloves mittens- the “second pair of hands” for snow and ice sports.

Modern ski gloves are precision-designed to achieve multifunctional protection.

1. The most basic protective function.

Ski gloves use waterproof fabrics like high-density Taslon, pongee, and Oxford cloth. They also have a waterproof, breathable membrane. This design helps keep snow and water out. The palm uses top-notch anti-slip and anti-cut materials. Its wear-resistant index is over three times higher than regular fabrics. This means it can handle friction and accidental bumps on the snow track effectively. The internal hollow fiber design (silk cotton) traps heat. This keeps your hands warm, even in 30°C weather.

2. Easy to operate, flexible design

Split-finger gloves have five separate fingers. This design makes it easy to grip poles. The anti-slip pattern on the fingers boosts friction to over 0.8. Three-finger gloves keep you warm and flexible. They’re great for snowboarders who need to adjust their gear quickly. Some high-end gloves have a touch-sensitive function. This lets you use smartphones while wearing gloves.

3. Innovative Ergonomics

The gloves have a double-sealed wrist. They use an elastic band and Velcro, boosting windproof efficiency by 40%. The adjustable cuff fits various wrist sizes. Also, the anti-lost cord helps prevent losing the gloves. The electric heated gloves feature a carbon fiber heating wire. This wire gives off steady heat.

Technological breakthroughs and industrial upgrading.

Ski gloves mittens have evolved with three main trends:

1. More eco-friendly materials, especially recycled polyester fiber.

2. Smart wearables are gaining popularity. Some premium gloves now include biosensors to track hand health.

3. Modular designs that allow for quick changes of palm pads, liners, and other parts.

In short, ski gloves mittens have changed a lot. From cold protection tools to technical gear, they show how snow sports are now more specialized. Their design meets the tough environmental challenges. It also shows the goal of creating the best sports experience. New materials and techniques are changing ski gloves. They’re no longer just protective gear. Now, they enhance snow and ice sports. This evolution pushes the limits of what we can achieve in these activities.

You might want to know: materials for custom gloves.

To custom gloves, consider their functionality, comfort, and safety. The materials fall into these main categories:

Shell fabric for custom gloves

1. Breathable and waterproof materials

High-density Pongee, Oxford cloth, nylon, and Taslon can block snow and water. They also have a microporous structure that lets moisture escape, keeping hands dry.

2. Abrasion- and tear-resistant materials

Some high-end gloves use Kevlar. This is the same material found in bulletproof vests, as well as in synthetic leather. This makes them strong against impacts and cuts. They are great for snowboarding and other sports where collisions occur.

Palm Material for custom gloves

1. Non-slip design: elastic terry cloth and anti-skid plastic drop molding. It includes a non-slip leather or soft rubber coating. This enhances grip on the snow poles and prevents slipping during use.

2. Shock-absorbing and cushioning: the inner lining uses fiber wool, memory foam, or EVA foam. This setup absorbs impacts and protects your wrist and finger joints effectively.

Lining and filling materials for custom gloves

1. Warmth layer: usually wool, cashmere, or neosherry cotton. These materials are light but great at keeping you warm. Some gloves also use shaker fleece or regular fleece for better breathability.

2. Touch screen function: The inner liner has conductive fiber or a special coating. This allows for touchscreen use with the gloves, making them more convenient.

High-tech materials for custom gloves

1. Nanotechnology treatment: The shell has a waterproof and anti-fouling nano-coating. This coating boosts durability and dirt resistance.

2. Smart temperature control: It uses phase change material (PCM) or graphene. This helps the temperature change based on different environments.

Other key designs for custom gloves

Sealed structure: The elastic wristband design keeps the fit snug. The non-slip zones on the thumb and index fingers stop snow from getting in.

Removable inner liner: easy to clean or swap out for various temperatures. This adds convenience.

In summary, the best material for custom gloves must balance several features. They need to be waterproof, breathable, abrasion-resistant, and warm. Also, ergonomic design is important to meet the various needs of outdoor sports.

Custom gloves manufacturing process

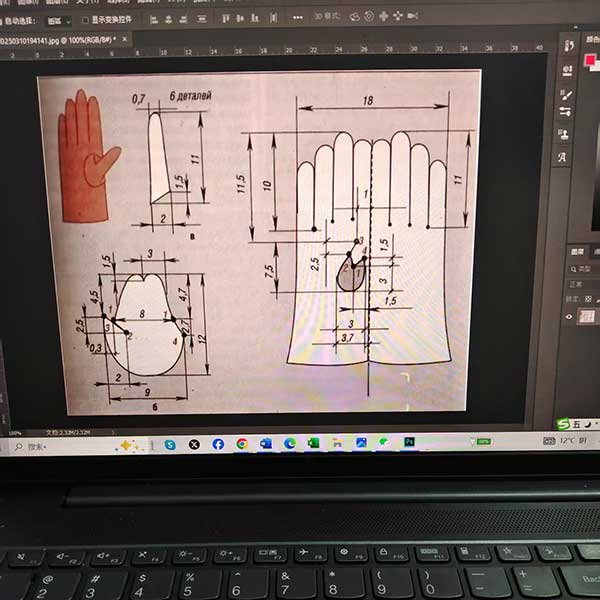

Computerized drawing

Designing and making drawings of glove parts on the computer. This process is very important. The shape and dimensions of the glove components must be correct and in accordance with the requirements. The workability of the product process is also taken into account during production. Reduce the complexity of the process and make it as simple and mass-producible as possible.

Glove parts cardboard

Use a CNC cutting machine to cut and shape pre-designed drawings on a computer.

Cardboard needs to be made of cardboard to facilitate the production of knife molds.

Making glove cutting molds

Make blade molds according to the cardboard model. Blade mold to use high carbon steel material according to the cardboard shape, for welding. The surface of the blade mold is cleaned and painted to prevent rust. After the knife mold is completed, it is inspected and qualified, and put into storage for use.

Cutting fabric

Calculate the total amount of fabric used for each cutout based on the number of gloves ordered. Cut off the total amount of fabric and lay it flat on the table in layers. Neatly stack and secure the edges of the cloth and set aside.

Glove knife mold cutting fabric

Neatly place the fabric, which is laid flat on the table, onto the cutting table. Cut according to quantities on production manufacturing sheets.

Gloves embroidered or printed

If the glove has an embroidery or print design, the worker must place the cut pieces separately in preparation for embroidery or printing.

Glove shell sewing

Sewing glove shells and assembling components. The splicing components should be sewn in the order of the product process. Require straight lines, no wrinkles, and even needle spacing to achieve the best quality.

Glove Lining Sewing

Sew glove liners and related accessories. Sew in the order of the process. Sewing lines should be strong and secure with no leaks. Accessories must be spliced in the correct position. The lining is sewn according to the process specifications and meets the quality requirements.

Glove Styling & Ironing

Place the gloves over the shaping mold and use an iron to smooth out the creases in the mittens. Heating the glove shaping mold with electricity to give the glove a three-dimensional and neat appearance.

Glove quality inspection

Finished making gloves, inspectors carefully check the glove shell and lining. Check the gloves for tears, stains, and threads. The spliced lines should be straight and beautiful, and the printing or embroidery should be clear and complete.

Gloves in OPP bag

Gloves that pass inspection are put into OPP bags by workers. If the gloves have customized labels, the labels need to be hung first, and then the gloves are placed flat into the OPP bags and sealed.

Gloves in a cardboard box

The Packers put the gloves into customized cartons according to the number of orders, and then seal the cartons in the warehouse.

Custom Gloves Ordering Process

1. Inquire before ordering

Please email or call us with the following details for your custom gloves:

• Style

• Size

• Material

• Quantity

• Color

• Printing (embroidery) content

• Packaging method

Then, we will send you a detailed quote.

2. Design and make samples

Once you accept the quote, we can create samples based on your drawings at no charge. You can also send us your samples. If you need to print (embroider) the logo layout, please pay a partial deposit (refundable). You need to pay the postage when we send the samples to you. To accept the quote, order from us, and pay a 30% deposit. We’ll then create a full sample and send it to you for free.

3. Start ordering

Once you have received the sample and confirmed its quality, we can proceed with signing the order contract and making a 30% advance payment. Confirm the production process, materials, quantity, and other needs first. Then we can start production.

4. Production customization

Procurement of materials and mass production. Delivery time will vary based on quantity and process. It typically takes between 7 and 30 days.

5. Inspection and delivery

After the production is completed, we will tell you. Once the inspection is qualified, you will make the final payment. Then, we will arrange to send it to the ship after we receive the payment.